Industrial Automation Solutions

GD Tech has over 10 years of experience in the design and manufacture of custom automation equipment. We are involved from the creation of initial concepts through engineering, fabrication, assembly, debug, installation and service. The systems we provide range from Pipe bender, winding machine to multi component, multi million dollar complete automated assembly production solutions. System configurations include standalone machines as well as modules to be integrated into production lines. Our custom automation equipment expertise will guarantee quality results for you production requirements.

We have incorporated numerous processes in the equipment we supply. Typical custom automation equipment applications will incorporate one or more of the following processes:

· Component Assembly · Die Set Integration · Dispensing / Curing · Film / Membrane handling · Label Print and Apply · Laser Marking / Bar Code · Pad Printing · Part Handling / Feeding | · Robot Integration · Testing - electrical / leak / flow / hydrostatic · Thermal Staking · Tray Loading / Unloading · Ultrasonic / Laser / Resistance Welding · Vision Inspection · Nanopositioning · Pin Insertion |

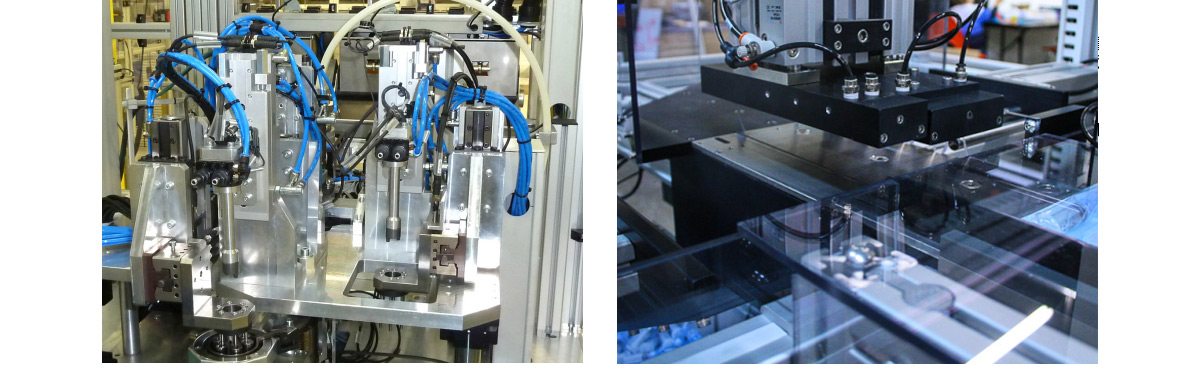

Automated Assembly Equipment

Designing and manufacturing custom automated assembly equipment has been GD Tech's core business since our start in 2003. GD Tech provides custom semi automated assembly equipment and fully integrated automated assembly equipment for a variety of applications and industries.

GD Tech's automated assembly equipment design begins by analysizing customers' products and processes to ensure the proper level of precision and accuracy is included to meet the system requirements. We then integrate component feeding systems with assembly equipment and test stations for a complete production solution.

GD Tech's experience enables us to offer our clients the appropriate customized automated assembly equipment solution to their automated assembly requirements.

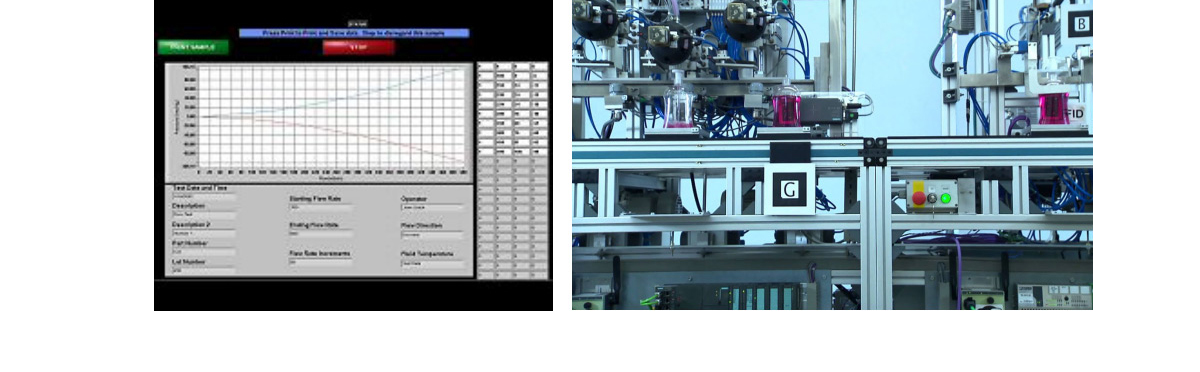

Automated Test Systems

GD Tech provides custom semi automated test systems and fully integrated automated test systems for a variety of applications and industries. We also design and build automated test systems for bench top and standalone applications.

GD Tech can design control system to test on sampling basis or provide 100% testing. We can also provide single or multi head testers based on your throughput requirements.

GD Tech's automated test systems experience includes:

· Air Flow Testing · Electrical Testing · Electro Mechanical Testing · Functional Testing · Hi Pot Testing · Hydrostatic Testing | · High Voltage Leak Testing

· Life Cycle Testing · Pressure Decay Leak Testing · Strain Gauge / Transducer Force Testing · Vision Inspection Stations (pattern and/or character recognition, dimensional inspection) |

All GD Tech Test Systems are designed to accurately and repeatedly test product to satisfy our customer's specifications and expectations. We know that the most important consideration when designing an automated test system is that it meets the highest standards in terms of repeatability and calibration throughout the life of the project.

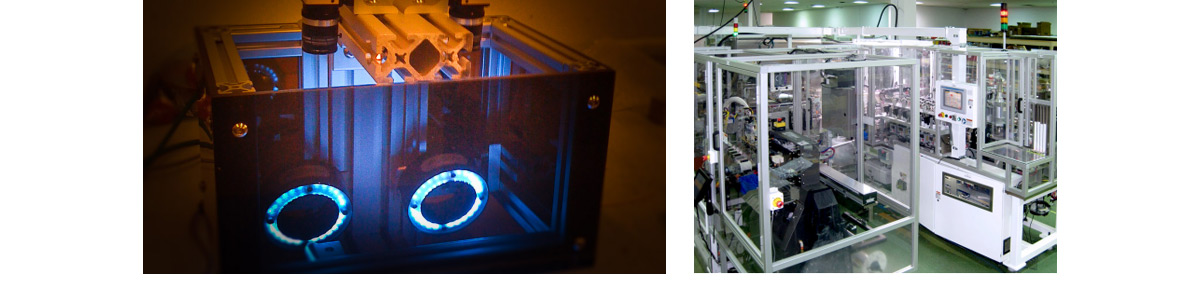

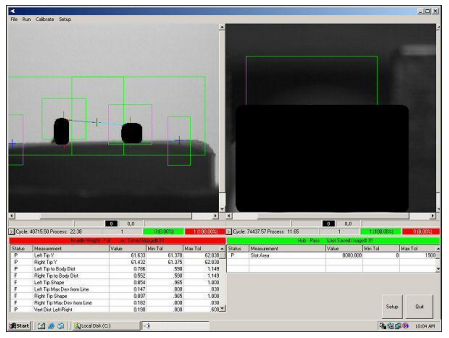

Machine Vision Systems

GD Tech is an experienced integrator of machine vision systems. This experience insures the quality of the products and processes that are manufactured by our custom automation equipment. Our experience insures that we will provide the right machine vision system to meet your specific application requirements.

GD Tech can provide either standalone machine vision inspection systems or a machine vision system fully integrated into production equipment. We integrate the most suitable machine vision solution for each application. Our machine vision solutions include application specific lighting, vision system programming and camera selection to provide a complete vision package.

GD Tech's machine vision system experience includes vision system programming and calculations in C++ and Visual Basic. It also includes application specific lighting design and integration of all major brands of vision systems including Cognex, DVT, Acuity and IPD.

Typical applications for machine vision systems are:

· Robot Guidance / Motion Control · Part Orientation and Dimensional Inspection · Pattern and/or Character Recognition · 2D and 3D Bar Code Reading · Label Inspection · Printing Inspection · Quality Control · Displacement Monitoring · Product Identification · Defect Detection · Assembly Confirmation |

|

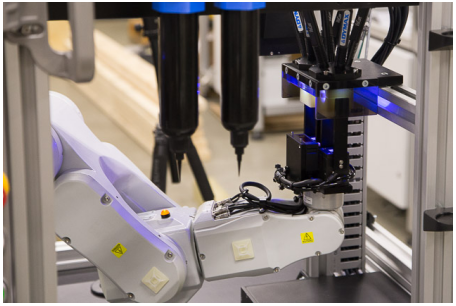

Robotic Systems Integration

GD Tech has integrated industrial robotic systems for applications that require 6-axis articulated robotic arms, 4-axis SCARA arms and 3 & 4-axis linear Cartesian robots. Advantages to a robotic system include shorter deliveries, quicker changeover and setup times for increased flexibility and efficiency. In addition, its flexibility allows for the ability to reuse the robot platform and retool for future applications quicker and at a less expensive cost than with standard "hard" automation. Robots also provide the flexibility for GD Tech to prototype applications quickly for our customers to prove out a process or technique. This enables our customers a cost effective up-front solution before committing to an equipment purchase.

GD Tech can develop a solution for any application that requires a flexible robotic system integration. we have designed standalone robotic cells and have also integrated robots into production equipment where a robot's flexibility is required.

Robotic System Integration Common Applications:

· Multi-Component Automated Assembly · Micro Assembly and Nano Positioning · Dispensing and Pipetting · Filling and Encapsulating · Test and Measurement · Labware and Drug Discovery Applications · Welding · Packaging · Vision Inspection · Tray Loading and Palletizing

|

|

Engineering Services

Over the last several years, GD Tech has expanded the scope of the engineering services to offer our customers with product and process development. This enables GD Tech to be involved earlier in the product life cycle, and to guarantee a seamless transition from R&D to production.

GD Tech has supported their customers in many applications including the following:

· Product Development

· Process Development

· Engineering Design – 2D & 3D, finite element analysis, drafting services

· Electrical & Controls Design – PLC, PC, HMI, LabVIEW, Wonderware, remote diagnostics, Stepper/Servo Motors

· CE Marking

· Validation Documentation – Functional Design Specification, Design Qualification Report, Factory Acceptance Test Protocol, Installation Qualification and Operational Qualification Protocols